Sales/Technical Consulting

+49 9187 9522-541

+49 9187 9522-50

gunther.brandenstein@frenco.de

Contact as vCard

Head Design

+49 9187 9522-518

+49 9187 9522-40

andreas.pommer@frenco.de

Contact as vCard

Universal Measuring Machines

Universal measuring machines record various characteristics of gears and splines in relation to an axis.

FRENCO offers different variants of machines that are set with Masters. Your batch size and test frequency defines the suitability of one or the other machine. From manual probing of geometrical elements, through to automatic, process-integrated test equipment, FRENCO offers a custom-made solution.

Basically, there are two variants:

Variants

- Runout, roundness and diametrical size on cylindrical elements

- Axial runout, flatness and distances on plane faces

- Pitch, runout, tooth thickness, lead and tip diameter in relation to an axis on gears and splines

- Probing on gears and splines is based on double flank contact

- Runout, roundness and diametrical size on cylindrical elements

- Double Flank Gear Test of gears

- Rolling Inspection of splines

- Evaluation of measurement results in relation to a defined axis

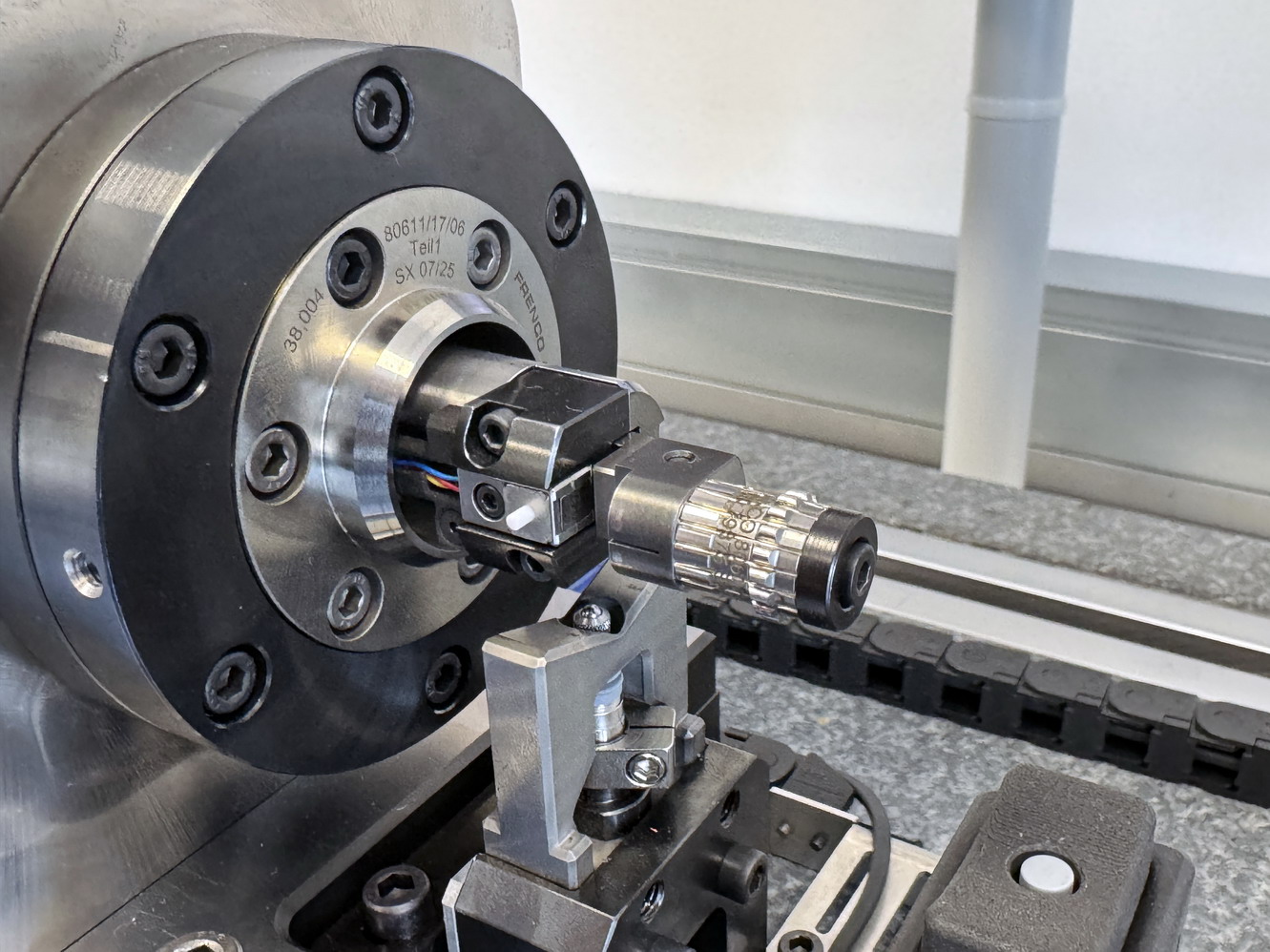

Manual Machine for High Flexibility

Machines with Ball Probe

- For external gears and splines

- Diameter and bearing seat inspection

- Output of runout, pitch and dimension over balls

- Ideal for random sample measurements on the shop-floor

- Very quick measurements due to manual operation

- Turret with various ball diameters

- Workpiece held between two centres, optionally with clamping chuck

- Axis and temperature compensation for high accuracy

- Max. diameter of specimen 230 mm, max. length 750 mm

- Evaluation by FRENCO Software RKpro

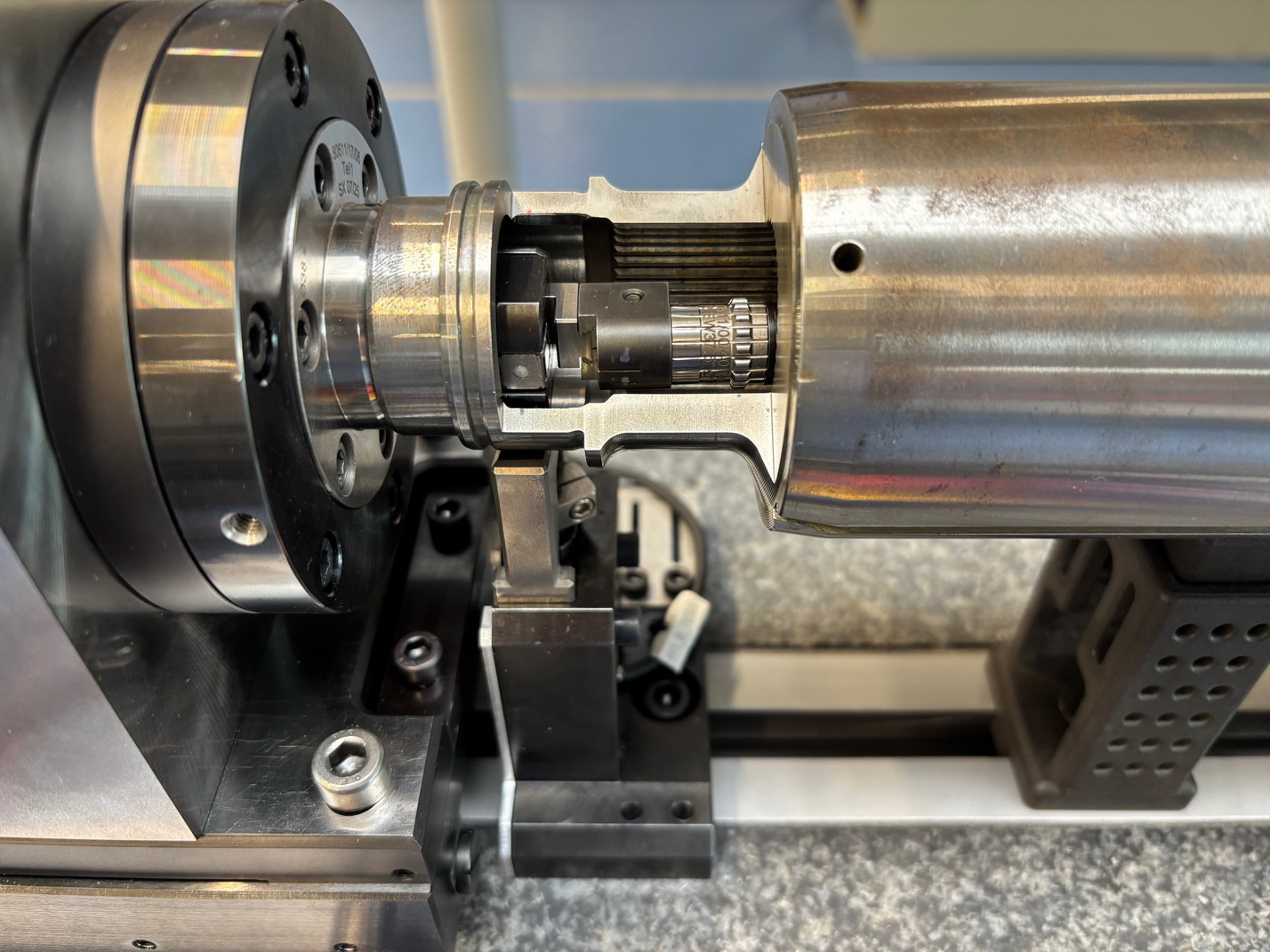

Horizontal Machine with NC control

Machines with Ball Probe

- For external gears and splines

- Diameter and bearing seat inspection

- Output of runout, pitch and dimension over balls

- Reliable and fully automated sample measurements on the shop-floor

- Programmable turrent with various ball diameters

- Workpiece held between two centres

- Axis and temperature compensation for high accuracy

- Max. diameter of specimen 230 mm, max. length 750 mm

- Evaluation by FRENCO Software URM-K

Variant for heavy weight loads:

- Specimen up to 30 kg

- Automatic part ejection

- Tip centre programmable, pneumatically activated

- Can be integrated in handling system

New: Horizontal measuring device for internally toothed shafts

Universal rotational measurement is based on a highly precise, robust and fast measuring system that was developed specifically for use in production environments. It is used to measure rotationally symmetrical workpieces such as shafts, gear wheels, threads, worms and special gear teeth.

The measuring system consists of three central components: the gear measuring device, a computer (standard PC) and a digital motor measuring box. In addition to converting the measured values, this measuring box also performs important control functions, processes the data and prepares it for transfer to the PC. The PC acts as a second evaluation unit and uses the RM Pro software to perform further processing, final evaluation and calculation of the measured values.

Digital measurement evaluation ensures exact reproducibility and documentability of all results. User-friendly visualisation of the measurements and results on the screen facilitates the measurement process and ensures a clear presentation of the test data.

The measurement process involves storing corresponding rotation angles and measured values in the measurement box. The workpiece is mounted on a floating rotary bearing – either on a headstock with a chuck or between centres against a tailstock – and measured during a continuous 360° rotation. Radially arranged measuring slides with transducers are positioned against the workpiece. During the rotational movement, the radial measured values are recorded and stored together with the rotational angle.

With universal rotational measurement, the diameters of non-toothed workpieces as well as internal and external gear teeth (even and odd) can be checked – in terms of dimensions, position and shape. Threads, worms and special gear teeth can also be measured precisely.

A particular strength of the system lies in the calculation of measurement results from different measuring points in the PC. This allows reference axes to be formed and deviations to be calculated for the determination of position tolerances. Position tolerances can thus be checked easily, quickly and with high accuracy in accordance with modern drawing tolerancing.

Vertical Machine with NC control

Machines with Ball Probe

- For internal and external gears and splines, ring gears and ball tracks

- Ideal for sample measurements on the shop floor

- Automatic probe change possible

- Workpiece held in 3-jaw chuck

- Axis and temperature compensation for high precision

- Max. diameter of specimen 300 mm, max. length 300 mm

- Evaluation by FRENCO Software URM-K

Inspection Machine for Shafts

Multiple Point Machines

- For external shafts with gears and splines

- Double flank gear inspection, rolling inspection and diameter inspection

- Record multiple features simultaneously (approx. 15 sec. per shaft)

- Workpiece held between two centres

- Max. diameter of specimen 230 mm, max. length 750 mm

- Customised design with up to eight measurement locations

- Tip centre programmable, pneumatically activated

- Can be integrated in handling system for 100%-inspection

- Evaluation by FRENCO Software RMpro

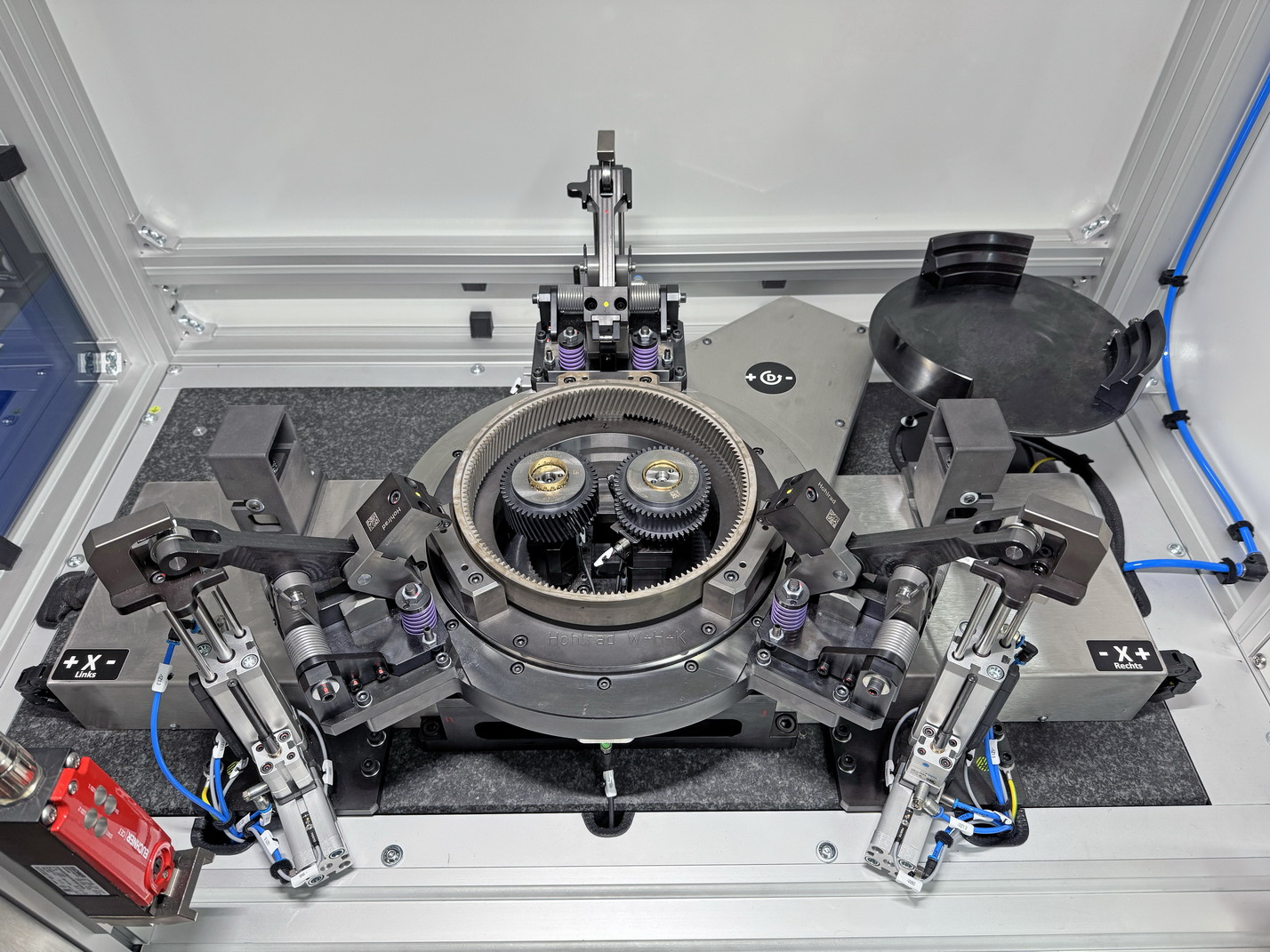

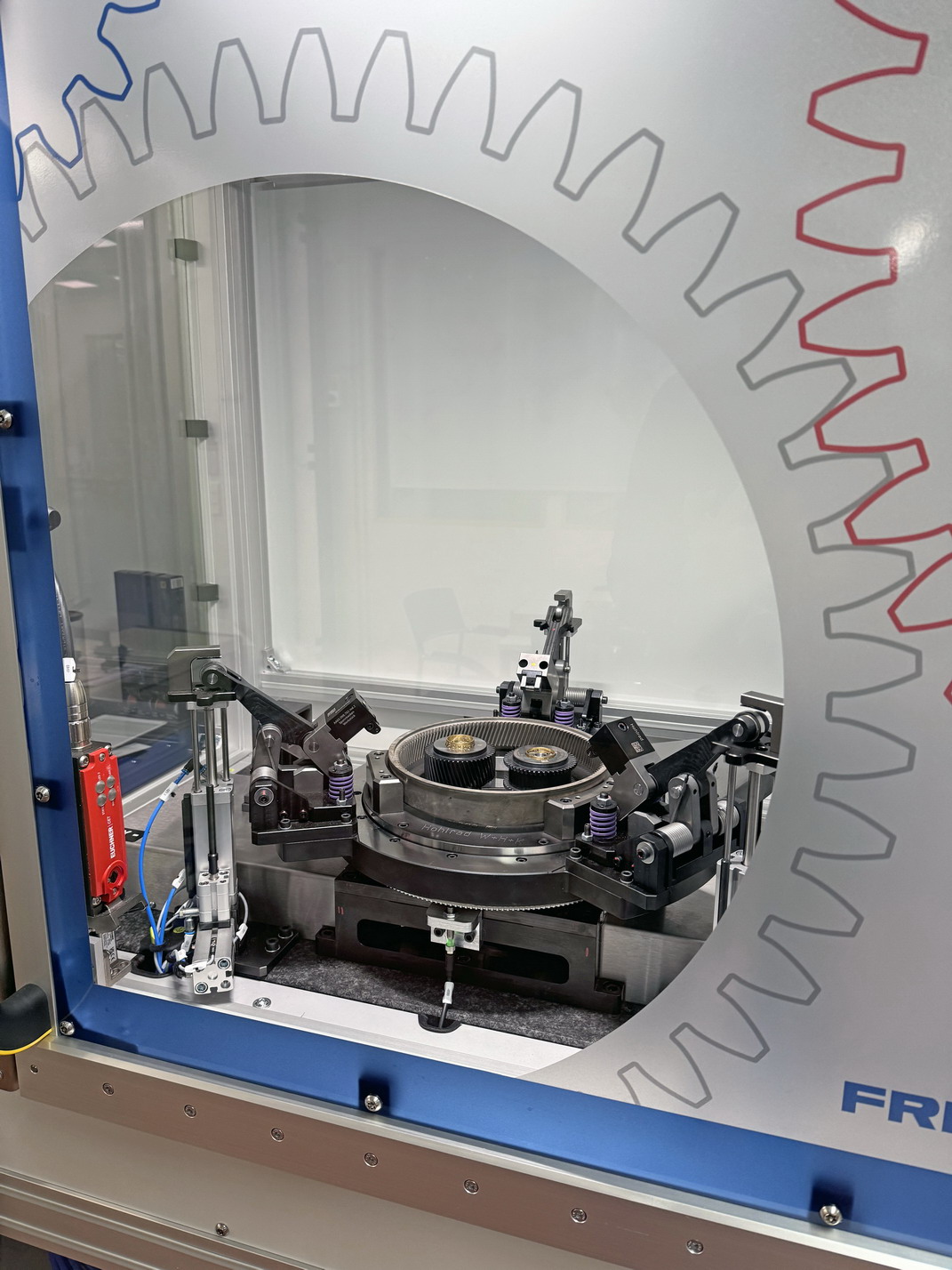

New: Inspection Machine for Ring Gears

- For internal gears

- Double flank gear inspection and diameter inspection

- Simultaneous recording of multiple characteristics

- 3-point clamping system

- Customised design

- Can be integrated in handling system for 100% inspection

- Evaluation with FRENCO-Software RMpro

Deutsch

Deutsch English

English